The Application of Line Scan Camera Lenses in Industrial Automation

In the realm of industrial automation, the need for precision and efficiency is paramount. One of the technological advancements that has significantly contributed to these goals is the line scan camera lens. Among the leading solutions in this space is the BASSON telecentric lens series, which combines high telecentricity, minimal distortion, and cost-efficiency to address the diverse demands of complex industrial environments.

Line scan camera lenses are pivotal in automated systems that demand high-speed and high-resolution imaging. Unlike traditional area scan cameras, which capture an entire image in a single frame, line scan cameras operate differently by capturing images one line at a time. This fundamental distinction offers significant advantages for continuous processes, particularly in industries like manufacturing and packaging.

In traditional area scan systems, each image frame represents a complete view of the scene, which can be limiting when dealing with long or continuously moving objects. These systems are more suited for static or semi-static imaging scenarios where the object being inspected does not change rapidly or extend beyond the field of view.

Line scan cameras, on the other hand, excel in applications where objects are in motion or where the scene extends over a large area. By capturing a single line of pixels at a time, these cameras can continuously build up an image of an entire object or surface as it moves past the camera. This approach is particularly advantageous for inspecting or measuring long, continuous surfaces, such as conveyor belts in manufacturing lines or rolls of material in packaging processes.

The ability of line scan cameras to handle high-speed operations makes them ideal for environments where speed and accuracy are crucial. For instance, in a manufacturing setting, a line scan camera can inspect products as they move along a conveyor belt, detecting defects or measuring dimensions with high precision. This continuous inspection process helps maintain product quality and reduce waste by catching issues in real time.

The BASSON telecentric lens series is distinguished by its exceptional performance characteristics, making it a superior choice for high-precision imaging applications. Telecentric lenses, including those in the BASSON series, are specifically designed to ensure that light rays entering the lens are parallel to the optical axis. This design is crucial for maintaining dimensional accuracy in imaging systems.

Telecentricity is a key attribute of these lenses. For the BASSON series, this is demonstrated by a telecentricity measurement of less than 0.05°. Telecentricity refers to the degree to which the lens maintains parallelism of the incoming light rays relative to the optical axis. High telecentricity is critical because it ensures that the scale of the image remains consistent across the entire field of view. This means that objects appear at their true size, regardless of their distance from the lens, and distortions are minimized.

In practical terms, this high level of telecentricity provided by the BASSON lenses is essential for applications where precise measurements and consistent image quality are required. For example, in industrial inspection systems where parts or products are measured, any variation in scale due to lens distortion can lead to inaccurate readings and potential quality control issues. The BASSON telecentric lenses mitigate these issues by providing a uniform scale, ensuring that measurements taken from the images are accurate and reliable.

This characteristic is particularly valuable in high-precision fields such as semiconductor manufacturing, where even minute deviations can have significant consequences. Similarly, in medical imaging or scientific research where precise quantification is necessary, maintaining dimensional accuracy is crucial. The ability of the BASSON series to deliver consistent image quality across the entire field of view supports these demanding applications.

The BASSON lens series offers a notable advantage with its exceptionally low distortion rate, measured at less than 0.05%. This characteristic is crucial in imaging applications where precision and accuracy are paramount. Distortion in lenses can cause significant errors by altering the apparent shape and dimensions of an object, which is particularly problematic in automated systems where exact measurements and inspections are required.

In imaging systems, distortion typically manifests as barrel or pincushion effects, where straight lines appear curved or the size of objects changes unevenly across the field of view. Such distortions can compromise the accuracy of measurements and the reliability of inspections. For instance, in quality control processes, distortion can lead to incorrect assessments of product dimensions or features, potentially allowing defective items to pass through inspection or resulting in unnecessary rejections of compliant products.

The BASSON lens series minimizes these issues with its low distortion rate, ensuring that the images captured are highly accurate representations of the actual objects. This low distortion is vital for several critical applications. In quality control, for example, the accurate representation of dimensions allows for precise verification against specifications, reducing the risk of faulty products reaching the market. In defect detection, minimal distortion helps in identifying defects accurately without the misleading effects of lens imperfections, ensuring that all potential issues are detected.

Dimensional verification is another area where low distortion is crucial. Accurate measurement of components, especially in high-precision industries like semiconductor manufacturing or automotive production, relies on the lens's ability to present true-to-life images. The BASSON lenses, by providing images with minimal distortion, support accurate measurements and facilitate reliable assessments of dimensional conformity.

The BASSON telecentric lens series stands out for its impressive cost-efficiency, which is a crucial factor for many industrial applications. Despite delivering high performance in terms of optical precision and minimal distortion, these lenses are designed to be economically viable. This careful balance between cost and performance makes advanced imaging technology accessible to a broader range of industries.

Achieving high performance in optical systems often involves significant investment, but the BASSON lenses are engineered to provide excellent value without sacrificing quality. This cost-efficiency means that companies can adopt advanced imaging solutions for their automation systems while managing their budgets effectively. Such affordability is especially important for industries that require multiple lenses or high-volume deployments, as the cumulative cost of imaging technology can be substantial.

For instance, in automated manufacturing lines, integrating high-quality telecentric lenses can enhance inspection processes, quality control, and precision measurements. However, if these technologies were prohibitively expensive, many companies might forego their adoption or settle for less accurate alternatives. The BASSON series addresses this issue by offering high performance at a lower cost, allowing companies to improve their production processes without experiencing significant financial strain.

Moreover, cost-efficient lenses enable businesses to scale their operations more effectively. As companies grow and their needs evolve, the ability to deploy advanced imaging systems across various stages of production or across multiple locations becomes more feasible. This scalability, coupled with the high performance of the BASSON lenses, supports ongoing innovation and optimization in industrial processes.

The versatility of the BASSON lenses is a key feature that significantly enhances their utility in various industrial applications. These lenses are designed to be compatible with large sensors, including full-frame and 8K 5µm line scan cameras, making them highly suitable for high-resolution imaging tasks. This adaptability is particularly important for industries where capturing fine details and achieving precise measurements are essential.

In automated systems, especially those used in semiconductor manufacturing and high-precision assembly processes, the ability to capture high-resolution images is crucial. Semiconductor manufacturing involves the production of extremely small and intricate components. Accurate inspection and measurement are essential to ensure that each semiconductor chip meets strict quality standards. The BASSON lenses' compatibility with 8K 5µm line scan cameras allows for exceptionally detailed imaging, enabling the detection of minute defects or deviations that might otherwise go unnoticed with lower-resolution systems.

Similarly, in high-precision assembly processes, where components must fit together perfectly and function reliably, detailed inspection is critical. The BASSON lenses facilitate this by providing high-resolution images that reveal fine details of the assembly, such as minute gaps or misalignments. This level of detail supports more accurate quality control and reduces the likelihood of errors that could compromise the integrity of the final product.

The ability to work with large sensors also enhances the versatility of the BASSON lenses, as they can cover wider fields of view without sacrificing resolution. This feature is beneficial for applications requiring broad coverage, such as inspecting large substrates or assembling multiple components simultaneously. The high resolution of full-frame sensors and 8K cameras ensures that even expansive areas can be examined with precision.

In terms of practical performance, the BASSON lenses offer a full range of depth of field (DOF) and field of view (FOV), which enhances their adaptability to various industrial environments. The lenses are capable of handling a wide range of wavelengths, which is beneficial in applications where different types of light or imaging conditions are required.

Moreover, the BASSON lenses incorporate TG+ multi-layer coating technology, which provides high transmittance and reduces reflections and glare. This coating ensures that the lenses can perform optimally in diverse lighting conditions, which is critical for maintaining image clarity and accuracy.

Industrial-grade waterproofing is another key feature of the BASSON telecentric lens series. In many industrial environments, exposure to dust, moisture, and other contaminants is a common challenge. The waterproofing ensures that the lenses remain functional and reliable even in harsh conditions, contributing to the overall durability and longevity of the imaging system.

In conclusion, the BASSON telecentric lens series exemplifies how advanced optical technology can enhance the efficiency and precision of industrial automation systems. By offering high telecentricity, low distortion, cost-efficiency, and versatility, these lenses address the complex needs of various industrial applications. Their ability to maintain image accuracy, adapt to different conditions, and provide reliable performance makes them an invaluable component in modern automated systems. As industries continue to evolve and demand higher levels of precision and efficiency, the role of advanced imaging technologies like the BASSON telecentric lens series will undoubtedly become increasingly significant.

Basson focuses on machine vision products used for precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems, telecentric lens systems, telecentric light sources, coaxial illuminations and optical lenses, but also offers customized services.

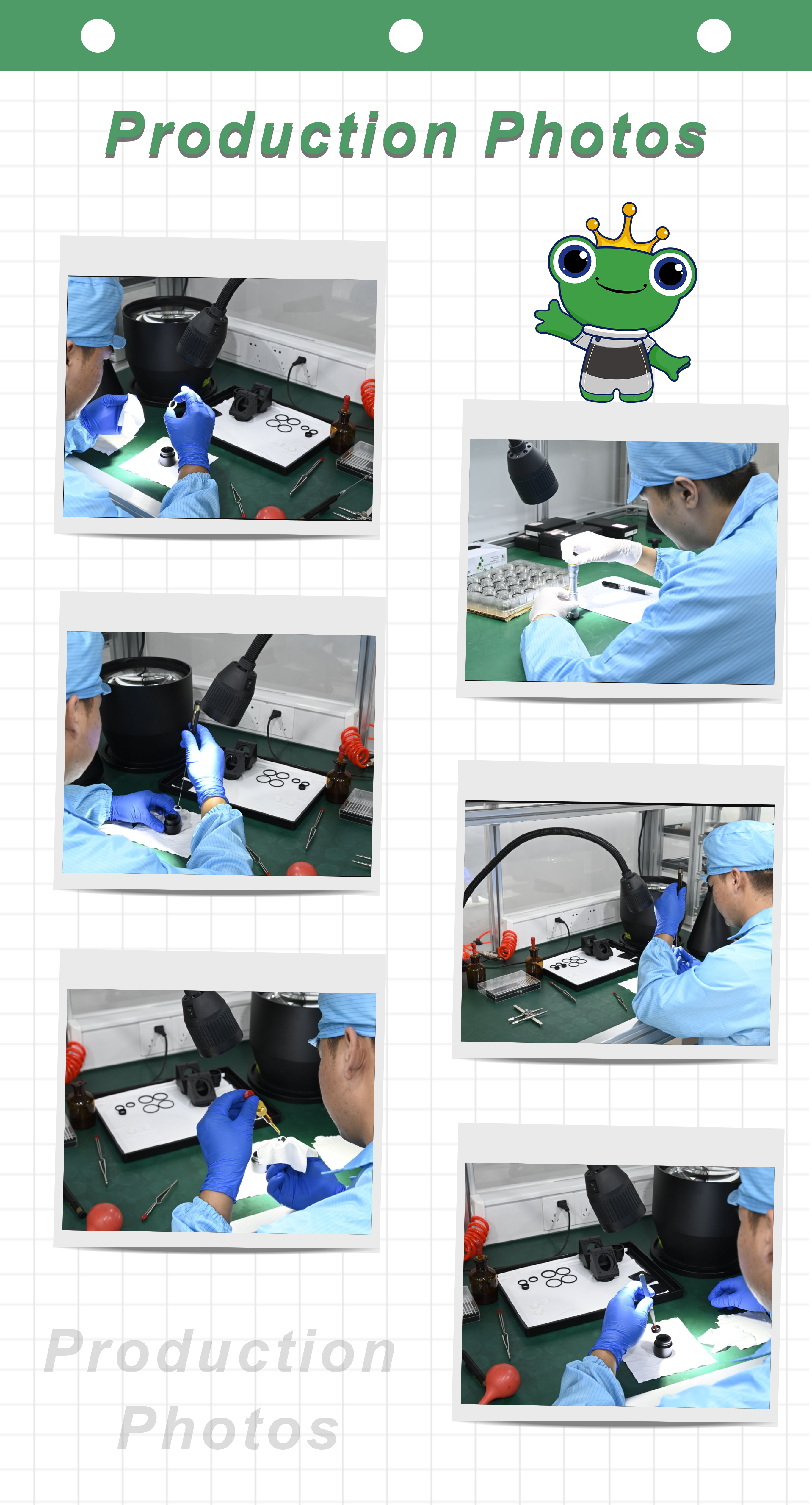

With products designed in Germany, business planned in the UK and products made in China, Basson is able to provide superior products to customers through its global team. Currently, Basson is in preparation of production and assembly of products in Japan.

Dr. Liu Lu, acting as CTO of Basson, is a PhD degree holder of Oxford University.

Production and testing instruments include optical vacuum coating machines manufactured by Satis in Switzerland and Leybold in Germany, a laser interferometer from Zygo in the US, a spectrophotometer from PerkinElmer in the US, a spherometer from Hofbauer Optik in Germany, a centering instrument from Kyoritsu Electric in Japan, a NC grinding device made by Kojima Engineering in Japan and an automatic centering machine made by Shonan in Japan.

Basson focuses on machine vision products used for

precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems,

telecentric lens systems, telecentric light sources,

coaxial illuminations and optical lenses,

but also offers customized services.