Role of Telecentric Lenses in Machine Vision Systems: Enhancing Image Accuracy and Measurement Reliability

In the realm of machine vision systems, achieving high image accuracy and measurement reliability is paramount. One of the pivotal components that significantly influence these attributes is the telecentric lens. Telecentric lenses, and their more specialized variants like bi-telecentric lenses, offer unique optical characteristics that address some of the critical challenges faced in industrial imaging and inspection applications.

Telecentric lenses are engineered to maintain a constant magnification ratio across the entire field of view. Unlike conventional lenses, where the magnification changes with the object’s distance from the lens, telecentric lenses are designed to produce images where the object’s size remains consistent, regardless of its position within the lens’s depth of field. This characteristic is crucial in machine vision applications where precise measurement and high image accuracy are required.

The fundamental principle behind telecentric lenses lies in their unique optical design, which involves aligning the lens's optical axis parallel to the object plane. This alignment is crucial for maintaining the lens's ability to deliver accurate and distortion-free images. In a standard lens system, perspective distortion occurs because light rays converge or diverge as they travel through the lens, causing objects to appear smaller or larger depending on their distance from the camera. This effect is particularly problematic in applications requiring precise measurements, as it introduces errors in size and spatial relationships.

Telecentric lenses address this issue by ensuring that the incoming light rays are parallel when they enter the lens. This is achieved through a combination of lens elements designed to keep the rays perpendicular to the image plane, regardless of the object's position within the depth of field. By maintaining this parallel alignment, telecentric lenses eliminate perspective distortion, allowing for accurate and consistent measurements of objects.

In practical terms, this means that objects will appear at their true size, regardless of their distance from the camera. For example, if you’re inspecting a part on a production line, a telecentric lens will allow you to measure dimensions such as width or height with high precision because the magnification remains constant across the entire field of view. This consistency is essential for quality control processes where even minor deviations can lead to significant errors.

The elimination of perspective distortion also enhances the reliability of machine vision systems. By reducing measurement errors that stem from perspective effects, telecentric lenses contribute to more accurate defect detection and dimensional analysis. This capability is vital in industries like semiconductor manufacturing, where even minute inaccuracies can have substantial implications for product performance and quality.

Telecentric lenses are integral to various high-precision applications, including automated inspection, quality control, and precision measurement. These lenses are specifically designed to maintain consistent image magnification and minimize distortion, regardless of the object's distance from the lens. This characteristic is crucial in automated inspection systems, where detecting minute defects or deviations in manufactured components is essential. Unlike conventional lenses, telecentric lenses have parallel light rays entering and exiting the lens, which ensures that measurements remain accurate even if the object's position changes slightly.

In high-speed production environments, where components move rapidly along assembly lines, telecentric lenses provide a stable and reliable means of inspection. This stability is particularly beneficial as it allows for real-time monitoring and measurement without being influenced by variations in object positioning. For instance, if a telecentric lens is used in a system designed to check the dimensions of parts, it will deliver precise measurements even if the parts are not perfectly aligned or are moving quickly. This capability enhances the efficiency of quality control processes, helping to ensure that only parts meeting stringent specifications are accepted. Consequently, telecentric lenses play a crucial role in maintaining product quality and consistency, making them indispensable in modern automated manufacturing and inspection systems.

Bi-telecentric lenses are a specialized type of telecentric lens that provides an additional layer of precision. They incorporate telecentric optics in both the imaging and object spaces, thus offering enhanced performance in applications that demand even greater accuracy and measurement reliability. This dual telecentric design ensures that the lens maintains its optical properties not only for the objects being imaged but also within the lens’s own optical system.

The bi-telecentric lens design is an advanced optical solution that enhances the capabilities of standard telecentric lenses by addressing their inherent limitations and offering superior performance in high-precision applications. Unlike conventional telecentric lenses, which maintain parallel light rays only in one plane—either the object plane or the image plane—bi-telecentric lenses uphold this parallel alignment in both planes. This dual-level telecentricity provides an even more consistent magnification and improved image fidelity across the entire field of view.

The primary advantage of bi-telecentric lenses is their ability to eliminate perspective distortion and ensure uniform magnification, regardless of the position or orientation of the object within the lens’s field. This is particularly crucial when dealing with large or irregularly shaped objects, or in applications requiring high magnification. In these scenarios, even minor deviations from the ideal telecentric alignment can result in significant measurement errors, compromising the accuracy and reliability of the data collected.

For instance, in precision measurement tasks where the dimensions of an object must be assessed with utmost accuracy, any distortion or inconsistency can lead to substantial errors. Bi-telecentric lenses address this challenge by ensuring that the optical axis remains parallel to the object and image planes. This results in a consistent magnification across the entire field of view, providing accurate and reliable measurements even for objects that are not centrally positioned or those with complex geometries.

Moreover, the bi-telecentric design minimizes depth-of-field issues and reduces aberrations that can affect image quality. By maintaining telecentric properties in both planes, these lenses offer exceptional performance in high-precision applications such as semiconductor inspection, micro-manufacturing, and quality control in high-tech industries.

Bi-telecentric lenses are increasingly vital in fields that require precise imaging and measurement, such as semiconductor inspection, high-resolution imaging, and advanced metrology. Their unique design, which maintains telecentric properties in both the object and image planes, is particularly beneficial in applications where accuracy is paramount.

In semiconductor inspection, for example, bi-telecentric lenses play a crucial role in examining microchips and other tiny components. These lenses are capable of delivering consistent magnification across the entire field of view, which is essential for detecting minute defects or irregularities in semiconductor devices. The ability to maintain uniform magnification and eliminate perspective distortion ensures that measurements remain accurate, regardless of the object’s position or orientation. This is crucial in semiconductor manufacturing, where even slight measurement errors can lead to significant operational problems, including faulty products and costly production downtime.

Similarly, in high-resolution imaging and advanced metrology, bi-telecentric lenses provide exceptional precision and image clarity. They are employed in applications such as optical inspections of complex mechanical parts, quality control in precision engineering, and detailed scientific imaging. By eliminating distortions and providing uniform magnification, these lenses enhance the accuracy of measurements and the quality of the images captured, which is critical for research and development, as well as for maintaining high standards in manufacturing processes.

Both telecentric and bi-telecentric lenses contribute to the enhancement of measurement reliability in machine vision systems. By addressing perspective distortion and providing consistent magnification, these lenses ensure that measurements are accurate and repeatable. This is particularly important in automated systems where consistency is key to maintaining quality and performance.

One of the critical benefits of telecentric lenses is their ability to facilitate precise dimensional measurement. In applications where exact measurements are required, such as in quality control processes, the use of telecentric lenses ensures that variations in object distance do not affect the measurement results. This capability is essential for applications like defect detection, where small deviations can indicate potential issues.

Bi-telecentric lenses further improve measurement reliability by providing superior image fidelity. This enhanced precision is particularly beneficial in applications where the lens must capture fine details and maintain accuracy over a large field of view. The ability to achieve high-resolution imaging with minimal distortion ensures that measurements are not only accurate but also reliable across different object sizes and shapes.

The role of telecentric and bi-telecentric lenses in machine vision systems is evident across various industries. In manufacturing, these lenses are used to inspect and measure parts with high precision, ensuring that products meet stringent quality standards. In the field of robotics, telecentric lenses enhance the accuracy of robotic vision systems, enabling robots to perform tasks such as pick-and-place operations with greater precision.

In scientific research, telecentric lenses are used in applications that require detailed imaging and measurement, such as in microscopy and material analysis. The ability to capture high-quality images without perspective distortion is crucial for conducting accurate experiments and analyses.

The implications of using telecentric and bi-telecentric lenses extend beyond accuracy and reliability. By improving the performance of machine vision systems, these lenses contribute to increased efficiency and reduced operational costs. For instance, in automated inspection systems, the use of telecentric lenses can lead to fewer false positives and negatives, reducing the need for manual intervention and increasing overall throughput.

Telecentric and bi-telecentric lenses play a critical role in enhancing image accuracy and measurement reliability in machine vision systems. Their ability to eliminate perspective distortion, maintain consistent magnification, and provide high-resolution imaging makes them invaluable tools in various industrial and scientific applications. As machine vision technology continues to advance, the importance of these lenses in ensuring precise and reliable measurements will only grow. Their contributions to improving the accuracy, efficiency, and performance of machine vision systems underscore their significance in the modern technological landscape.

Basson focuses on machine vision products used for precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems, telecentric lens systems, telecentric light sources, coaxial illuminations and optical lenses, but also offers customized services.

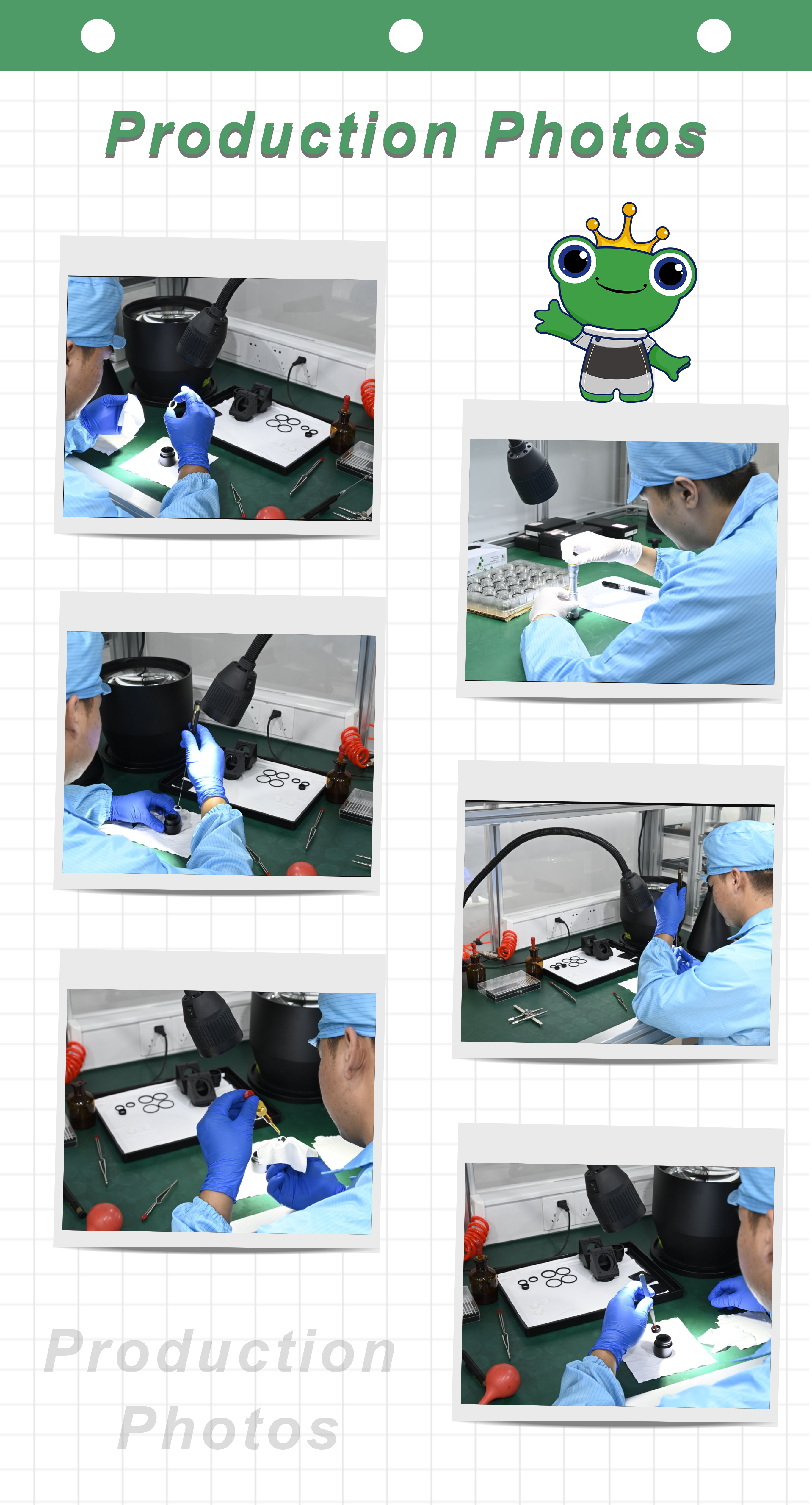

With products designed in Germany, business planned in the UK and products made in China, Basson is able to provide superior products to customers through its global team. Currently, Basson is in preparation of production and assembly of products in Japan.

Dr. Liu Lu, acting as CTO of Basson, is a PhD degree holder of Oxford University.

Production and testing instruments include optical vacuum coating machines manufactured by Satis in Switzerland and Leybold in Germany, a laser interferometer from Zygo in the US, a spectrophotometer from PerkinElmer in the US, a spherometer from Hofbauer Optik in Germany, a centering instrument from Kyoritsu Electric in Japan, a NC grinding device made by Kojima Engineering in Japan and an automatic centering machine made by Shonan in Japan.

Basson focuses on machine vision products used for

precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems,

telecentric lens systems, telecentric light sources,

coaxial illuminations and optical lenses,

but also offers customized services.