Enhancing the Stability of Machine Vision Systems: Advances in Bi-Telecentric Lenses

In the rapidly evolving landscape of automation and smart technology, machine vision systems have become indispensable across various industries. These systems are designed to replicate the capabilities of human vision, enabling machines to interpret and analyze visual data with remarkable accuracy and speed. However, for machine vision to be truly effective, stability is paramount. One of the most significant advancements in achieving this stability is the development of bi-telecentric lenses.

At the core of machine vision systems is the need for precise measurements and reliable data interpretation. Stability in this context refers not only to the physical stability of the optical components but also to the consistency of the images captured under varying conditions. Any fluctuations, distortions, or aberrations in the image can lead to inaccurate readings, which can compromise the integrity of the entire system. Industries such as manufacturing, quality control, and robotics heavily rely on machine vision for tasks like inspection, identification, and navigation, making the pursuit of stability critical.

Historically, traditional lenses utilized in machine vision systems have faced significant challenges due to various optical distortions, such as field curvature, chromatic aberration, and perspective distortion. These distortions can severely impact image quality, particularly in high-precision applications where even minor inaccuracies can result in substantial errors. For instance, in sectors like manufacturing and quality control, where precise measurements are critical, any optical aberration can compromise the reliability of the data collected. As a result, engineers and researchers have actively sought innovative solutions to overcome these challenges. Among these advancements, bi-telecentric lenses have emerged as a groundbreaking option. These lenses are specifically designed to minimize optical distortions by ensuring that the chief rays of light entering the lens are parallel to the optical axis. This design feature not only reduces perspective distortion but also maintains consistent magnification across varying object distances, thereby enhancing measurement accuracy. Additionally, bi-telecentric lenses allow for controlled illumination, which helps eliminate shadows and highlights that can obscure important features in the image. By addressing the limitations of traditional lenses, bi-telecentric lenses represent a significant leap forward in machine vision technology, enabling industries to achieve greater precision and reliability in their imaging applications. As the demand for high-quality visual data continues to grow, the adoption of bi-telecentric lenses will likely play a crucial role in advancing the capabilities of machine vision systems.

Bi-telecentric lenses represent a significant advancement in optical design, particularly for machine vision applications. One of the key features of these lenses is their ability to ensure that the chief rays of light entering the lens are parallel to the optical axis. This unique configuration effectively minimizes perspective distortion, a common issue with standard lenses that can lead to inaccuracies in dimensional measurements. In traditional lens systems, variations in object distance can result in different magnification levels, complicating the measurement process and potentially leading to errors. However, bi-telecentric lenses maintain a constant magnification regardless of how far the object is from the lens. This consistent performance is particularly advantageous in automated inspection systems, where precision is paramount.

The benefits of bi-telecentric lenses extend beyond distortion reduction and consistent magnification. Their design incorporates two distinct optical paths—one dedicated to capturing the image and the other for providing illumination. This dual-path approach enhances image quality by allowing for controlled lighting, which helps to reduce shadows and highlights that could obscure important features of the object being analyzed. In automated inspection scenarios, where every detail counts, the clarity and accuracy provided by bi-telecentric lenses can significantly improve the reliability of inspection results.

Moreover, the reduced optical distortion inherent in bi-telecentric lenses enables them to produce sharper images with improved detail resolution. This is crucial in applications that require high levels of accuracy, such as semiconductor manufacturing or quality control in automotive parts production. The precise imaging capabilities of bi-telecentric lenses facilitate better data analysis and interpretation, supporting advanced machine learning algorithms that rely on high-quality visual data.

The bi-telecentric design of lenses plays a crucial role in enhancing both image quality and measurement accuracy, making them an essential component in advanced machine vision applications. One of the standout features of bi-telecentric lenses is their ability to provide controlled illumination. This capability is instrumental in minimizing shadows and highlights that can obscure critical features of the objects being analyzed. By evenly illuminating the target, bi-telecentric lenses ensure that important details are clearly visible, leading to sharper, more distinct images. This clarity not only aids in accurate measurements but also facilitates more effective analysis and interpretation of the visual data, allowing operators and systems to make better-informed decisions quickly.

Moreover, bi-telecentric lenses are designed to maintain a constant magnification across the entire field of view. This characteristic is particularly advantageous in environments where objects of varying sizes are frequently encountered. Unlike standard lenses, which may require recalibration when switching between different object dimensions, bi-telecentric lenses eliminate this necessity. This consistency in magnification means that operators can seamlessly transition from inspecting one size of an object to another without worrying about measurement discrepancies.

In high-speed production lines, where time and efficiency are of the essence, this feature is invaluable. The reduced need for recalibration not only speeds up the inspection process but also minimizes potential downtime. As production speeds increase, the demand for precise and reliable measurement systems becomes even more critical. Bi-telecentric lenses rise to this challenge by providing dependable performance, ensuring that each product meets quality standards without sacrificing speed.

Additionally, the design of bi-telecentric lenses contributes to enhanced depth of field, further improving their utility in complex inspection tasks. This allows for a more comprehensive view of the object being analyzed, capturing multiple features simultaneously and reducing the need for multiple camera setups.

Moreover, the advances in materials and manufacturing processes for bi-telecentric lenses have contributed to their increasing reliability and performance. High-quality glass and advanced coatings minimize reflections and enhance light transmission, which is crucial for applications operating in low-light environments or requiring high dynamic range. These advancements not only improve image quality but also extend the lifespan of the optical components, reducing the need for frequent replacements or maintenance.

The integration of bi-telecentric lenses into machine vision systems is a significant advancement that aligns seamlessly with the principles of automation and Industry 4.0. As manufacturing environments evolve into more interconnected and intelligent systems, the demand for precise, real-time data becomes paramount. Bi-telecentric lenses excel in this context by delivering stable, high-resolution images that are crucial for accurate analysis. Their ability to maintain consistent magnification and minimize optical distortions ensures that machine learning algorithms can process visual data rapidly and effectively. This enhances decision-making processes by providing operators with reliable insights into product quality and process performance. Consequently, manufacturers can optimize production efficiency, reduce waste, and quickly respond to emerging issues on the production line. In essence, bi-telecentric lenses not only meet the rigorous demands of modern industrial environments but also contribute to the broader goal of creating smarter, more efficient manufacturing systems.

In addition to industrial applications, the benefits of bi-telecentric lenses extend to other fields such as biomedical imaging, robotics, and research. For instance, in medical applications, accurate imaging is crucial for diagnostics and research, where even slight discrepancies can affect outcomes. Bi-telecentric lenses enable researchers and practitioners to obtain high-quality images with minimal distortion, thereby improving the reliability of their findings.

As machine vision technology advances, the integration of bi-telecentric lenses with cutting-edge technologies like artificial intelligence (AI) and deep learning promises significant enhancements in performance and functionality. Bi-telecentric lenses already provide high-quality imaging with minimal distortion and consistent magnification, making them ideal for precise measurements in various industrial applications. When paired with AI and deep learning algorithms, these lenses can leverage their superior imaging capabilities to feed high-fidelity data into analytical systems that can learn and adapt over time.

This combination enables machine vision systems to recognize patterns and anomalies with greater accuracy, allowing them to adjust to varying conditions in real-time. For example, in a manufacturing setting, an AI-powered system can analyze images captured by bi-telecentric lenses to detect defects or variations in product quality that may not be visible to the human eye. As the system processes more data, it becomes increasingly adept at distinguishing between acceptable and unacceptable quality levels, significantly improving inspection speed and accuracy.

Moreover, the synergy between bi-telecentric lenses and advanced analytics enhances overall system stability. Intelligent algorithms can optimize imaging parameters dynamically, adjusting for changes in lighting conditions or object positioning. This adaptability not only reduces the likelihood of errors but also enhances the reliability of the entire inspection process.

The future of machine vision lies in the ability of these intelligent systems to operate autonomously. By continuously monitoring, analyzing, and optimizing processes without human intervention, industries can achieve unprecedented levels of efficiency and productivity. Real-time insights generated from bi-telecentric lens data can inform decision-making processes, leading to quicker responses to issues and improved overall operational efficiency.

In conclusion, the advancements in bi-telecentric lenses represent a pivotal step toward enhancing the stability of machine vision systems. By addressing the challenges of optical distortions and providing consistent, high-quality imaging, these lenses enable industries to achieve greater precision and efficiency. As the demand for reliable machine vision continues to grow across various sectors, the importance of stable and accurate optical systems will only become more pronounced. Ultimately, bi-telecentric lenses not only enhance the capabilities of machine vision systems but also pave the way for more advanced and intelligent automation solutions in the future.

Basson focuses on machine vision products used for precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems, telecentric lens systems, telecentric light sources, coaxial illuminations and optical lenses, but also offers customized services.

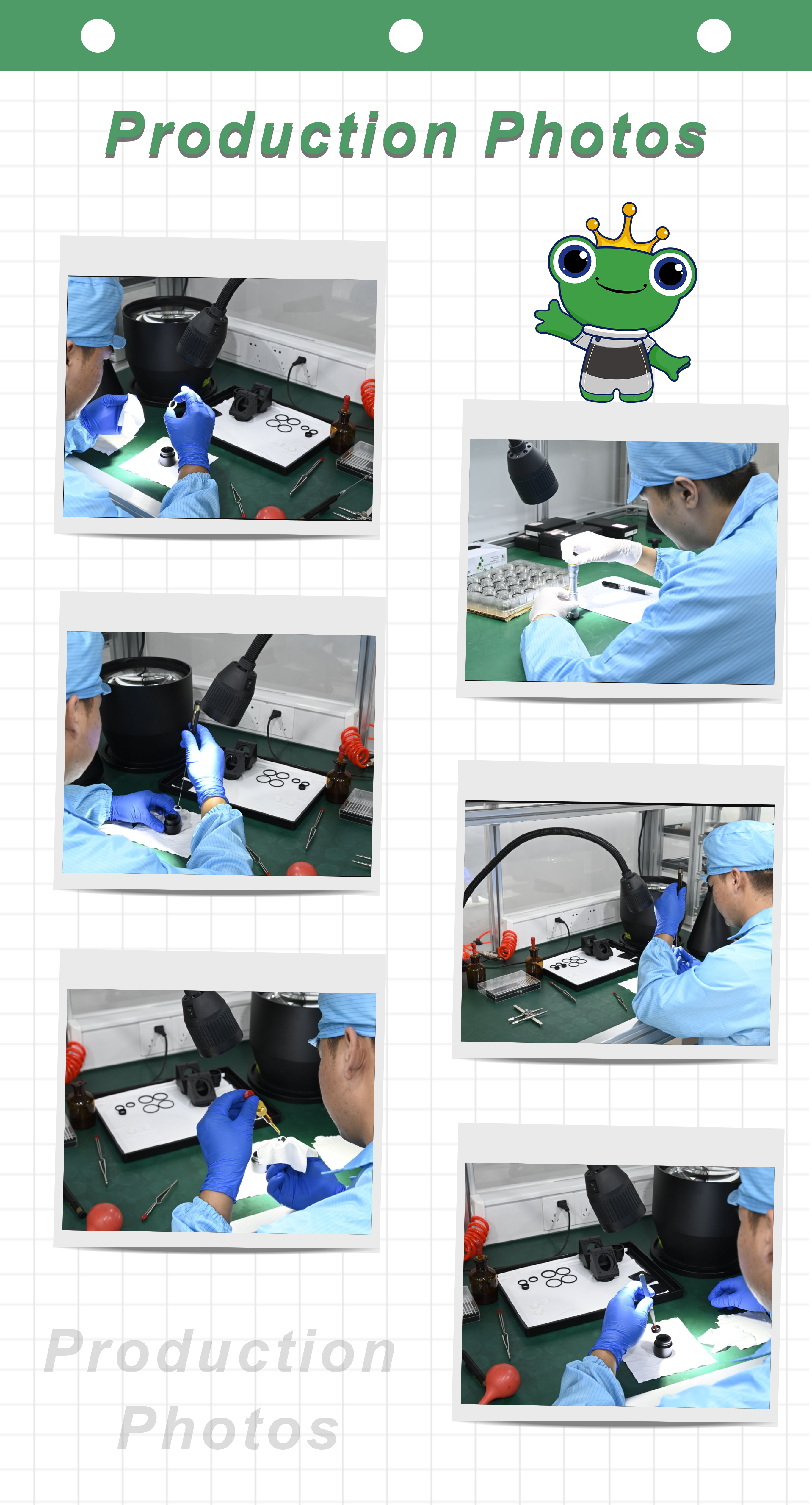

With products designed in Germany, business planned in the UK and products made in China, Basson is able to provide superior products to customers through its global team. Currently, Basson is in preparation of production and assembly of products in Japan.

Dr. Liu Lu, acting as CTO of Basson, is a PhD degree holder of Oxford University.

Production and testing instruments include optical vacuum coating machines manufactured by Satis in Switzerland and Leybold in Germany, a laser interferometer from Zygo in the US, a spectrophotometer from PerkinElmer in the US, a spherometer from Hofbauer Optik in Germany, a centering instrument from Kyoritsu Electric in Japan, a NC grinding device made by Kojima Engineering in Japan and an automatic centering machine made by Shonan in Japan.

Basson focuses on machine vision products used for

precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems,

telecentric lens systems, telecentric light sources,

coaxial illuminations and optical lenses,

but also offers customized services.