Comparing the Performance Differences Between Liquid Lenses and Traditional Lenses

The advent of advanced optical technologies has led to significant innovations in the field of imaging, particularly in lens design. Among these innovations are liquid lenses, which have emerged as formidable alternatives to traditional glass lenses.

Liquid lenses, such as the BASSON liquid telecentric lens series, are distinguished by their unique performance attributes that significantly enhance their functionality in industrial applications. One of the standout features of these lenses is their exceptional telecentricity. Unlike traditional lenses, which often suffer from variable magnification depending on the distance of the object, liquid lenses maintain a constant magnification across different distances. This attribute is particularly vital in precision measurement environments, where even minor discrepancies can lead to significant errors. By ensuring that the angles of light entering the lens remain consistent, liquid lenses effectively mitigate the measurement errors commonly associated with perspective distortion. This is crucial in industrial settings where accurate dimensional analysis is required, such as in the production of intricate components where tolerances are tight, and precise specifications must be adhered to.

The telecentricity of liquid lenses is primarily achieved through their innovative design, which allows for adjustments in the optical path. This flexibility means that even when the object distance changes, the lens can adapt without sacrificing the integrity of the image. In contrast, traditional lenses typically rely on fixed focal lengths and cannot compensate for distance variations as effectively. Consequently, measurements taken with traditional lenses may fluctuate, leading to inconsistencies in data capture and analysis. This discrepancy is particularly problematic in industries where stringent quality control is paramount. Furthermore, the high telecentricity of liquid lenses facilitates easier integration with advanced imaging systems and software, enabling seamless data processing and analysis.

Another advantage of liquid lenses is their ability to provide a greater depth of field, ensuring that objects at varying distances remain in focus. This feature is especially beneficial in automated inspection systems, where multiple components are analyzed simultaneously. Traditional lenses may struggle with depth of field limitations, requiring additional adjustments or multiple captures to achieve satisfactory focus across different object planes. The combination of high telecentricity and a broader depth of field in liquid lenses results in enhanced image quality and reliability, making them an ideal choice for industries that depend on accurate imaging for quality assurance and measurement tasks. This technological advancement places liquid lenses at the forefront of optical innovation, solidifying their role in the future of industrial imaging solutions.

The BASSON series of liquid lenses represents a significant advancement in optical technology, particularly noted for their remarkably low distortion rate, which is less than 0.05%. This feature is crucial for applications where precision is of utmost importance, such as metrology and quality control processes. In these contexts, even minor distortions can lead to significant inaccuracies, affecting the reliability of measurements and the overall quality of the products being inspected or manufactured. Traditional lenses, on the other hand, can exhibit higher levels of distortion, which can compromise the integrity of image capture and analysis. The capability of liquid lenses to minimize distortion not only enhances measurement accuracy but also ensures that intricate components can be manufactured with greater confidence in their dimensional specifications. This reliability is particularly important in industries such as aerospace, automotive, and electronics, where even slight deviations can have far-reaching consequences.

In addition to their impressive distortion characteristics, liquid lenses also offer remarkable adaptability, which further contributes to their performance advantages. One of the key features of liquid lenses is their adjustable working distance. Unlike traditional lenses that have fixed focal lengths and are optimized for specific distances, liquid lenses allow users to fine-tune their optical characteristics to suit various operational requirements. This flexibility is particularly beneficial in industrial settings where the size and distance of objects can vary significantly. For example, in a manufacturing environment, operators may need to inspect components of different sizes and shapes, requiring quick adjustments to the optical setup. Liquid lenses can easily accommodate these changes, allowing users to maintain optimal focus and clarity without the need for multiple lens replacements or cumbersome recalibrations.

Moreover, the adaptability of liquid lenses enhances overall imaging quality by enabling fine-tuning of focus, which is critical in dynamic environments. Traditional lenses can be limited in their versatility, often necessitating specific distances to function effectively. This can hinder workflow efficiency, as operators might spend valuable time adjusting setups or switching out lenses to achieve the desired imaging results. In contrast, the ability of liquid lenses to adapt to varying conditions streamlines operations, allowing for faster turnaround times and improved productivity. By minimizing the time spent on optical adjustments, companies can focus on their core processes, ultimately enhancing output quality and operational efficiency.

The low distortion rates and adaptability of liquid lenses position them as a superior choice in many applications, particularly where high precision and flexibility are essential. Their performance in minimizing optical inaccuracies not only benefits individual measurements but also contributes to the overall quality assurance processes within industrial operations. The introduction of liquid lenses into metrology and quality control frameworks signifies a shift toward more advanced optical solutions, enabling industries to meet the increasingly stringent demands for accuracy and efficiency. As these technologies continue to evolve, it is expected that their adoption will grow, paving the way for innovations in various fields reliant on precision optics. The advantages presented by liquid lenses mark a significant milestone in optical engineering, illustrating the importance of continuing to push the boundaries of what is achievable in lens design and application.

The BASSON liquid telecentric lens series stands out in the optical landscape due to its impressive range of depth of field (DOF) and field of view (FOV), making it particularly suitable for applications that demand comprehensive imaging capabilities. One of the critical advantages of these lenses is their ability to capture sharp, high-resolution images across varying distances. This feature is essential in numerous industrial scenarios where precise imaging is necessary for tasks such as quality control, inspection, and measurement. The versatility offered by the BASSON series enables operators to maintain optimal focus on multiple components simultaneously, thereby enhancing the efficiency of industrial processes. In environments where depth perception is crucial, the capability to achieve a broad field of view without compromising image quality allows for a more comprehensive assessment of products or systems being examined.

In addition to their impressive optical performance, liquid lenses excel in their ability to effectively image across a wide spectrum of wavelengths. This broad spectral response enhances their applicability in diverse environments and for various applications, from visual inspection to more specialized tasks requiring infrared or ultraviolet imaging. Such flexibility is invaluable in industries like pharmaceuticals, electronics, and materials science, where different wavelengths may be necessary to evaluate material properties or detect specific defects. Traditional lenses, while effective in many general applications, often fall short in providing the same level of functionality, particularly in specialized scenarios that require precise wavelength management. This limitation can hinder their effectiveness in environments where the accurate representation of features across different wavelengths is critical.

Moreover, the BASSON liquid telecentric lens series is designed to minimize optical aberrations, ensuring that image quality remains consistently high, regardless of the operational conditions. The combination of extensive depth of field, wide field of view, and the ability to operate across various wavelengths positions these lenses as superior choices in modern industrial applications. By effectively addressing the demands of high-resolution imaging and flexibility, the BASSON series empowers operators to tackle a broader range of challenges, paving the way for more innovative solutions in the fields of inspection and quality assurance. As industries continue to evolve and embrace advanced technologies, the importance of reliable optical systems, such as those provided by the BASSON series, will only grow, underscoring the need for precision and adaptability in today's fast-paced manufacturing landscape.

Another crucial aspect of liquid lenses is their multi-layer coating, which results in high transmittance. The TG+ multi-layer coating employed in the BASSON series enhances the lens's ability to transmit light effectively, reducing loss and ensuring brighter, clearer images. In comparison, traditional lenses may not always feature such advanced coatings, which can lead to lower image quality due to light loss and reflections. High transmittance is particularly vital in low-light conditions, where the performance of the lens can significantly impact the visibility and clarity of the captured image.

The industrial-grade waterproofing of liquid lenses further distinguishes them from traditional lenses. In environments where dust, moisture, and other contaminants can pose risks to equipment, the robust design of liquid lenses ensures durability and reliability. This feature makes them particularly suitable for use in challenging conditions, such as manufacturing facilities or outdoor settings, where traditional lenses may be more susceptible to environmental factors. The ability of liquid lenses to withstand harsh conditions while maintaining performance integrity is a critical consideration for industries that rely on consistent and accurate imaging.

Cost efficiency is another area where liquid lenses can provide significant advantages. While the initial investment in liquid lens technology may be comparable to traditional systems, the long-term benefits, including reduced maintenance costs and enhanced performance capabilities, often make liquid lenses a more economical choice over time. The ability to adjust working distance and minimize distortion can lead to improved production efficiency and lower operational costs, further solidifying the case for their adoption in industrial applications.

In conclusion, the performance differences between liquid lenses and traditional lenses are profound and impactful, particularly in industrial contexts. The high telecentricity, low distortion rate, adjustable working distance, and superior imaging capabilities of liquid lenses like the BASSON series present a compelling case for their use in precision measurement and imaging applications. Coupled with advanced features such as high transmittance and waterproofing, liquid lenses offer a level of versatility and reliability that traditional lenses may struggle to match. As industries continue to seek innovative solutions to enhance their processes, the adoption of liquid lenses represents a significant advancement in optical technology, promising improved accuracy, efficiency, and overall performance in a wide range of applications.

Basson focuses on machine vision products used for precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems, telecentric lens systems, telecentric light sources, coaxial illuminations and optical lenses, but also offers customized services.

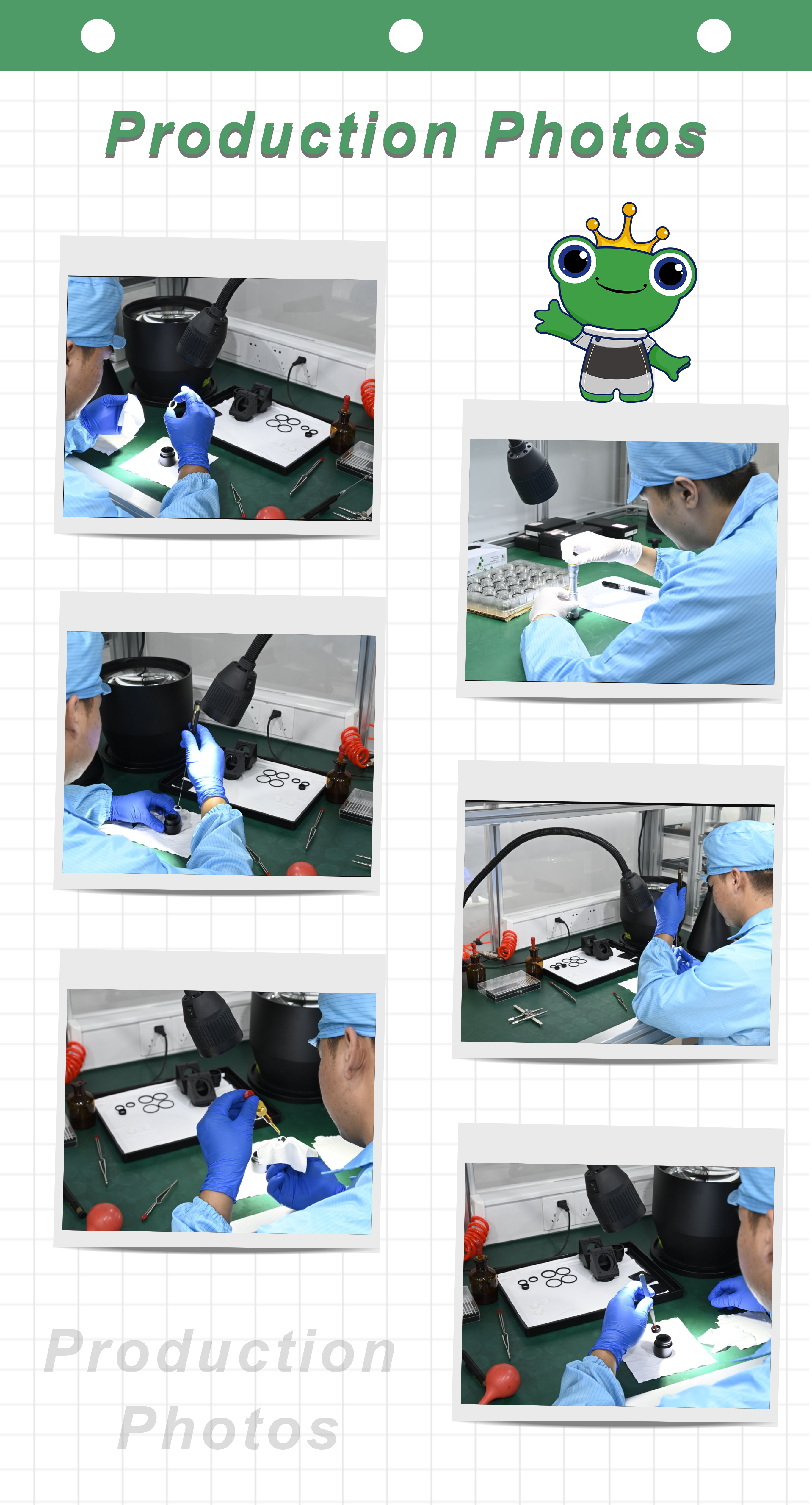

With products designed in Germany, business planned in the UK and products made in China, Basson is able to provide superior products to customers through its global team. Currently, Basson is in preparation of production and assembly of products in Japan.

Dr. Liu Lu, acting as CTO of Basson, is a PhD degree holder of Oxford University.

Production and testing instruments include optical vacuum coating machines manufactured by Satis in Switzerland and Leybold in Germany, a laser interferometer from Zygo in the US, a spectrophotometer from PerkinElmer in the US, a spherometer from Hofbauer Optik in Germany, a centering instrument from Kyoritsu Electric in Japan, a NC grinding device made by Kojima Engineering in Japan and an automatic centering machine made by Shonan in Japan.

Basson focuses on machine vision products used for

precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems,

telecentric lens systems, telecentric light sources,

coaxial illuminations and optical lenses,

but also offers customized services.