The Fine Polishing of Glass Lens Raw Material: Achieving Optical Perfection through Cold Processing

The fine polishing of glass lens raw materials is a critical process in the manufacturing of high-quality optical lenses. It requires a deep understanding of material properties, precise handling, and expert control over the polishing process to ensure that the final product meets the rigorous standards required for various optical applications. Although the lens may look smooth and round after fine grinding, its surface still contains a number of imperfections, such as scratches, pits, and other defects, that are not visible to the naked eye but are revealed under a microscope. These imperfections, however minor they may appear, can have a profound effect on the optical performance of the lens, making them unacceptable for most applications. This is where fine polishing, especially using softer materials and specific polishing agents, comes into play. Through careful adjustment of processing parameters, the lens can be perfected, ensuring the highest optical clarity and performance.

At the initial stage of optical lens production, the lens undergoes grinding to eliminate larger surface imperfections and to shape it according to specific design requirements. This grinding process involves the use of coarse abrasives that work to remove substantial material from the lens, bringing it closer to the desired form. As the grinding progresses, the lens appears progressively smoother to the naked eye, and one might assume that it is ready for use. However, despite its seemingly smooth exterior, the surface is still far from flawless when examined under a microscope. The grinding process, although effective at removing gross imperfections, often leaves behind microscopic defects that cannot be seen without magnification. These include tiny scratches, pits, micro-cracks, and irregularities that are the byproducts of the abrasive action of grinding wheels. Even though they are not visible to the human eye, these imperfections can significantly degrade the optical performance of the lens.

The defects caused by the grinding process are primarily due to the nature of the abrasives and the grinding method itself. Coarse abrasives, while efficient at removing material, tend to create surface irregularities that are detrimental to the final optical quality. These surface flaws can scatter light, causing distortion, aberrations, and a reduction in the clarity and sharpness of images produced by the lens. To address this, standard grinding methods are no longer sufficient. The lens must undergo further refinement to remove these minute imperfections, a process known as fine polishing.

Fine polishing is necessary to achieve the ultimate smoothness and transparency required for high-performance lenses. Unlike grinding, fine polishing utilizes much softer polishing materials and finer abrasives, often combined with specific polishing agents. This process is designed to smooth out the microscopic defects left behind by the grinding phase, working at a much finer scale to achieve a perfect, defect-free surface. During fine polishing, the abrasives gradually wear away any remaining scratches, pits, and surface imperfections, leaving the lens with a flawless optical surface that meets the stringent requirements for optical clarity and precision.

To effectively eliminate defects in lens surfaces, a combination of specialized techniques and carefully chosen materials are employed to ensure that the lens meets the highest optical standards. One of the primary techniques used is soft polishing, where materials such as polishing leather are utilized for their ability to gently smooth the lens surface without exacerbating existing scratches. The polishing process typically involves the use of a liquid that contains microscopic abrasive particles, typically ranging in size from 0.2 to 3 microns. These tiny particles work gradually to refine the surface, removing any residual marks or imperfections left behind from the grinding phase. This polishing technique is often referred to as "cold polishing" due to its focus on minimizing heat generation, which is crucial in preventing any thermal distortion that could negatively affect the lens.

Moreover, to maintain the lens's integrity, precise control over several critical processing parameters is required. These include the rotation speed of the polishing equipment, the pressure applied, and the amplitude of the swing of the polishing pad. Each of these factors plays a crucial role in determining the final surface quality. For instance, the rotation speed dictates the polishing rate, while the pressure ensures effective material removal without damaging the delicate lens surface. Similarly, the amplitude of the swing—how much the polishing pad moves—affects the uniform distribution of the polishing compound, ensuring that the entire surface of the lens is polished evenly.

The careful adjustment of these parameters is essential to achieve the desired optical performance. For lenses to meet rigorous standards, manufacturers must fine-tune these factors to balance the removal of surface defects while maintaining the lens's critical optical properties, such as its rise deviation, aperture size, and Yas value—each of which contributes to the lens's overall performance. By optimizing these variables, manufacturers can ensure that the lenses not only meet the desired level of clarity and precision but also retain their structural and optical integrity throughout the polishing process. Through this intricate control, they achieve a finely polished surface that meets both aesthetic and functional standards.

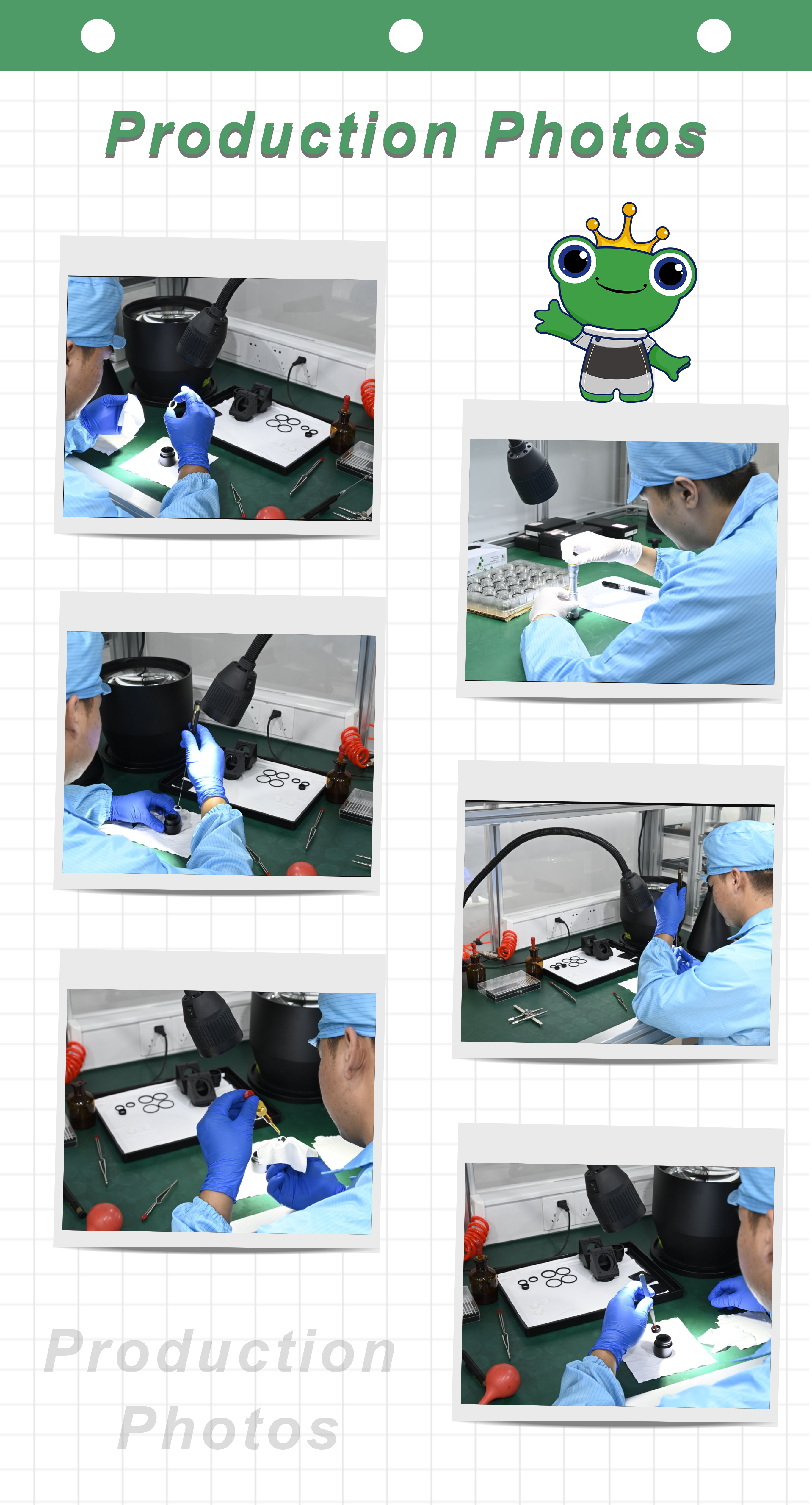

Once the polishing process is complete, the lens is inspected under a microscope to assess the effectiveness of the refinement. At this stage, the true transformation of the lens becomes apparent. What was once a surface riddled with microscopic defects now appears entirely smooth and flawless. The glass, which previously exhibited tiny scratches, pits, and irregularities, is now perfectly transparent, free from any imperfections that could distort the path of light. This critical examination reveals a surface that will not scatter light or cause optical aberrations, allowing the lens to function at its full potential. What began as a raw, flawed material is now a polished optical surface that meets the stringent demands of industries such as photography, medical optics, and precision instrumentation, where clarity and accuracy are paramount.

The fine polishing process itself is a delicate and intricate operation that demands significant expertise. It is not just a mechanical task but a precise art, requiring a combination of skill, experience, and careful attention to the minutiae. The use of softer polishing materials, like polishing leather, ensures that the lens is smoothed without introducing new flaws or micro-scratches. Coupled with highly refined polishing agents, which consist of abrasives fine enough to smooth out even the tiniest defects, the process transforms the lens into an optical tool of superior quality. The careful control of the polishing parameters—such as the pressure applied, the speed of rotation, and the duration of the process—plays a key role in achieving the desired result. A slight variation in any of these factors could lead to imperfections that would compromise the lens's optical properties.

Furthermore, the fine polishing stage is not just about creating a smooth surface but ensuring that the lens retains its intended optical characteristics. Achieving a flawless surface is not sufficient if the lens does not meet critical specifications like sharpness, clarity, and absence of distortion. The fine polishing process ensures that the lens can achieve the required optical performance, delivering clear, sharp images with minimal light distortion. In industries like medical imaging or high-precision photography, these qualities are indispensable, and the final polished lens must perform reliably under demanding conditions. Therefore, the fine polishing of lenses is not a mere finishing touch but a vital component of the production process, ensuring that the final product exceeds rigorous standards of quality and reliability.

Through the meticulous polishing of the lens, manufacturers ensure that every optical element, no matter how small, is carefully refined to meet the demands of its intended use. The fine polishing process, which involves cold processing and precise control over polishing agents and parameters, ensures that the lens is free from surface defects and ready for its final application. After the lens is polished and inspected under a microscope, it gleams with perfection, offering the clarity and transparency required for precise optical work. In the world of optics, where precision and quality are paramount, the fine polishing process is the key to achieving optical perfection, transforming a raw lens into a high-performance optical instrument.

In conclusion, the fine polishing of glass lenses is an essential process in optical lens production. Despite the apparent smoothness of a lens after fine grinding, the presence of microscopic defects means that further polishing is necessary to achieve the required level of optical clarity. The use of soft polishing materials, refined polishing agents, and precise control over the polishing process allows manufacturers to remove these defects and achieve a surface free from imperfections. By carefully adjusting processing parameters, such as rotation speed, pressure, and swing amplitude, the lens is polished to meet stringent optical standards. The result is a lens that is not only smooth and transparent but also capable of delivering exceptional optical performance for a wide range of applications. The fine polishing process is thus integral to the production of high-quality optical lenses, ensuring that every lens, no matter its application, meets the exacting standards required for modern optical systems.

Basson focuses on machine vision products used for precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems, telecentric lens systems, telecentric light sources, coaxial illuminations and optical lenses, but also offers customized services.

With products designed in Germany, business planned in the UK and products made in China, Basson is able to provide superior products to customers through its global team. Currently, Basson is in preparation of production and assembly of products in Japan.

Dr. Liu Lu, acting as CTO of Basson, is a PhD degree holder of Oxford University.

Production and testing instruments include optical vacuum coating machines manufactured by Satis in Switzerland and Leybold in Germany, a laser interferometer from Zygo in the US, a spectrophotometer from PerkinElmer in the US, a spherometer from Hofbauer Optik in Germany, a centering instrument from Kyoritsu Electric in Japan, a NC grinding device made by Kojima Engineering in Japan and an automatic centering machine made by Shonan in Japan.

Basson focuses on machine vision products used for

precision measurement and defect detection.

Basson not only provides high-precision bi-telecentric lens systems,

telecentric lens systems, telecentric light sources,

coaxial illuminations and optical lenses,

but also offers customized services.